Hello

Jonny Cage Features and Specifications

There's much to see here. So, take your time, look around, and learn all there is to know about us. We hope you enjoy our site and take a moment to drop us a line.

Comparisons to Competitors and Jonny Cage Frequency Response Curves

Features and Specifications

High fidelity percussion instrument recording

High fidelity percussion instrument recording

High fidelity percussion instrument recording

The Jonny Cage was designed for the music industry by a drummer/electrical engineer for live performances and high fidelity percussion instrument recording.

Features Video

High fidelity percussion instrument recording

High fidelity percussion instrument recording

Here's a short video illustrating some of the features of the Jonny Cage.

Road Box-Jonny Cage Transformer

High fidelity percussion instrument recording

Road Box-Jonny Cage Transformer

The Jonny Cage ships in its own “road box” configuration. Two road box configurations transforms into the Jonny Cage. No need to buy or store extra shipping containers. The Jonny Cage is a logistics dream come true.

10dB-20dB noise reduction

Versatile acoustic recording

Road Box-Jonny Cage Transformer

Over 10dB noise reduction centered at 1200 Hz (Cycloidal panel shape) and 20 Hz (booth height) control the sound inside and out of the booth for smooth and clean audio recording. The unique design eliminates annoying reflected sound waves inside and outside of the cage. Unwanted “snare rattle” is virtually eliminated.

Versatile acoustic recording

Versatile acoustic recording

Versatile acoustic recording

Since the booth was designed to capture the “worst case” wide frequency bandwidth inherent in percussion instruments, it also excels for recording any instrument (guitars/piano/sax and vocals). Replace the drums with a couch, floor lamp, and coffee table and you’ve got the perfect setting for acoustic recording.

Convection Ventilation

Versatile acoustic recording

Versatile acoustic recording

A sound attenuating ventilation system provides a convective ventilation system while an internal roof baffle blocks unwanted sound transfers into and out of the booth.

Features and Specifications

4 Gang Microphone Trolley

How to Disassemble a Road Box for the Jonny Cage

How to Disassemble a Road Box for the Jonny Cage

An internal microphone trolley accommodates up to four (4) microphones or microphone goosenecks. This feature allows the freedom to locate the microphones anywhere along the track for precise microphone placement. This feature eliminates the need for microphone stands and frees up valuable floor space. In most situations, multi channel drum mounted microphones are not necessary and can be eliminated.

How to Disassemble a Road Box for the Jonny Cage

How to Disassemble a Road Box for the Jonny Cage

How to Disassemble a Road Box for the Jonny Cage

This video illustrates how to disassemble a Jonny Cage Road Box (two total). The Road Box parts are transformed into a 6x6 foot -10dB sound reduction drum booth chamber.

Acoustic Divider

How to Disassemble a Road Box for the Jonny Cage

Removable Accessory Pouches

A microphone acoustic divider panel isolates microphones from each other for extremely clean right/left, front/back, channel separation.

Removable Accessory Pouches

Curtain Panel Pockets and Weights

Removable Accessory Pouches

Configurable removable internal pouches and “pouch bus” provide storage for drum sticks, cell phones, sheet music or even beverages. The pouches can be placed anywhere on the bus.

Curtain Panel Pockets and Weights

Curtain Panel Pockets and Weights

Curtain Panel Pockets and Weights

Each panel has incorporated weight pouches for flexible weights. Optional weights enhance the panel’s cycloidal shape, further attenuating unwanted sound reflections at the low frequency bandwidth.

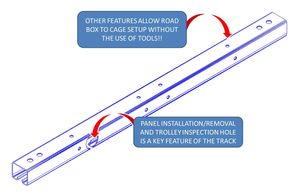

Trolley Idler Inspection Ports

Curtain Panel Pockets and Weights

Curtain Panel Pockets and Weights

The Trolley roller installation/inspection ports are provided for effortless panel to cage assembly and disassembly.

Features and Specifications

Clear View Removable Windows

How to Assemble a Road Box after Disassembly of the Jonny Cage

How to Assemble a Road Box after Disassembly of the Jonny Cage

Each panel comes with a clear .040 thick removable window incorporating the same cycloidal design as the panel while providing a full 360 degrees of visual contact between the drummer and other performers, conductors and sound professionals.

How to Assemble a Road Box after Disassembly of the Jonny Cage

How to Assemble a Road Box after Disassembly of the Jonny Cage

How to Assemble a Road Box after Disassembly of the Jonny Cage

This video illustrates how to assemble a Jonny Cage Road Box (two total).

The Jonny Cage structural assembly is transformed from a 6x6 foot -10dB sound reduction drum booth chamber into two(2) road boxes for transporting.

Washable Panels

How to Assemble a Road Box after Disassembly of the Jonny Cage

Road Box to Jonny Cage Transformation

The panels and roof components are washable. Panel weights, windows and pouches are easily removed to accommodate panel washing.

Road Box to Jonny Cage Transformation

Road Box to Jonny Cage Transformation

Road Box to Jonny Cage Transformation

The “Road Box” construction utilizes the steel already used for the Jonny Cage assembly, reducing shipping/logistic weight and eliminates packing material waste.

Tool less Assembly

Road Box to Jonny Cage Transformation

Integrated Caster Capture Plates

No tools or tape measures are required for assembly. The Jonny Cage has been designed for ease of transport and assembly.

Integrated Caster Capture Plates

Road Box to Jonny Cage Transformation

Integrated Caster Capture Plates

Quick and easy removal of casters. The capture plates are also designed to be used in the Jonny Cage as lighting brackets.

Features and Specifications

Integrated Lighting

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Booth

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Booth

Using the caster capture plates, our LED lighting brackets span either from column to column horizontally or can be mounted vertically along a column. Horizontal lighting can be doubled using our capture plates. Additionally, the capture plates can slide up and down the columns and be locked in place.

Visit our store to see our lighting accessories that facilitate a myriad of lighting installation configurations.

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Booth

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Booth

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Booth

There are two videos illustrating the Jonny Cage assembly. Part 1 (this video), illustrates how to assemble the Jonny Cage structural components while Part 2, illustrates how to integrate the roof, side panels, windows and panel weights.

The two(2) road boxes used for transporting the Jonny Cage are disassembled and are then transformed into the Jonny Cage structure.

Hardware haversack

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Booth

Two Piece carpet flooring

A three (3) compartment haversack neatly and conveniently stores the hardware for cage assembly. Once the Jonny Cage is assembled, the haversack makes a nice storage compartment for any number of accessories.

Two Piece carpet flooring

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Roof and Panels

Two Piece carpet flooring

The two (2) piece Carpet flooring enhances the sound proofing qualities while preventing drum kit sliding and creep. The carpet also accurately locates the base plates without the use of a tape measure.

Each of the base plates have four(4) mounting holes to facilitate permanent mounting installations if desired.

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Roof and Panels

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Roof and Panels

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Roof and Panels

There are two videos illustrating the Jonny Cage assembly. Part 1 illustrates how to assemble the Jonny Cage structural components. Part 2, (this video) illustrates how to integrate the Jonny Cage roof, panels, windows and weights.

The two(2) road boxes used for transporting and storing the roof and panels of the Jonny Cage are disassembled and then transformed into the Jonny Cage.

Stuff Box

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Roof and Panels

How to assemble the Jonny Cage 6X6 Free Standing -10dB Attenuating Drum Roof and Panels

Included in the transformation from the Road Box to Jonny Cage is what we refer to as the “Stuff Box”.

This is an extra storage container for the Road Box castors and Road Box Covers. On the top of the Stuff Box is a nice tray for drummers to empty their pockets, place a beverage or even place a mixing board.

Copyright © 2022 jonnycageproacoustics.com - All Rights Reserved.